Sico PMS & Sico SPC

Maintain control over the production at all times

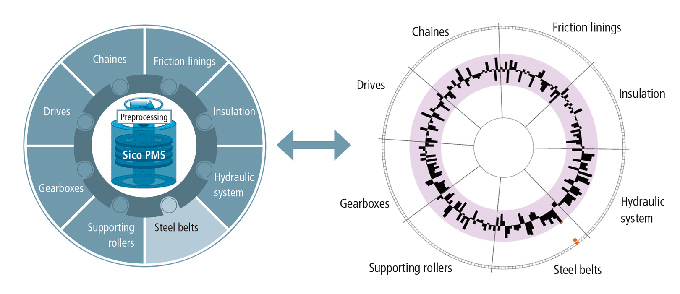

Performance monitoring system Sico PMS

Knowing today about the future machine performance with Sico PMS

Siempelkamp’s Performance Monitoring System Sico PMS guarantees the most efficient production of wood-based products – a production that safely makes use of the lifespan of all wear components and no longer wastes valuable component life. Maintenance management, machine condition monitoring, and preventive maintenance are some goals of intelligent production.

Excellently suitable as a retrofit

The answer to this is the newly developed Siempelkamp Performance Monitoring System for ContiRoll® presses, based on the new computer technology of the SPC Generation III. It includes: fast and highly accurate sensors, real-time capable computer technology, software modules for the evaluation of the machine condition, machine parameter limits for optimum low-wear operation, web-based user interface, interface for the automatic notification of modern information technologies, and the secure remote access to data. With this system customers receive all evaluations and strategies for the use of status data – up to the preventive maintenance.

Thanks to its compatibility with any sensor technology, Sico PMS is excellently suitable as a retrofit to improve the production processes of existing plants. Sico PMS can be tailored to individual needs and is extendable to meet future tasks, for example, when the drive of the ContiRoll® is converted to the energy-efficient ContiRoll Ecodrive system.

Press controller Sico SPC

For a safe production process: 20,000 measuring values and Sico SPC

The intelligent pressure and position control system, Siempelkamp Press Controller Sico SPC, uses raw data from pressure and position sensors for the control of the desired press forces and distances between cylinders in the technological press zones of the ContiRoll®. To be a part in shaping today’s and future demands on the digitalization in machinery and plant engineering, Siempelkamp developed the new Sico SPC Generation III.

Extremely powerful hardware

The new Sico SPC is based on state-of-the-art hardware technology, uses proven Siempelkamp system architecture and the Ethernet-based fieldbus PROFINET-IO for ultrafast measurement value logging. Processors with multi-core architecture provide the Sico SPC with outstanding computing power. In the course of upgrades to existing plants, the new Sico SPC Generation III replaces SPC systems of the first and second generation without any problem. PROFINET replaces INTERBUS S interfaces; following minor adjustments, the programs for the pressure and position control are integrated. Established tool chains as well as existing hardware configurations remain unchanged after the upgrade to Sico SPC.

Futher information

Ihr Ansprechpartner

Manuel Thiesen

Tel. +49 2151 92-4839

manuel.thiesen@sls.siempelkamp.com